We Care Abouth Your Prosperity

INDUSTRIAL AUTOMATION

How We Do it?

PARAGROUP AİS offers turnkey project design, automation software, system installation, documentation, breakdown maintenance and technical services in the mining, petrochemical and gas industries. Our experience and experience in automation systems and our open attitude to development and innovation enable you to reach the highest quality with confidence.

As the PARAGROUP AIS, it has established Industry 4.0 infrastructure for many global companies for many years, and has made PLC Software, SCADA Software, Data Collection and Reporting Software, SAP / ERP Integration, Cloud Server Configuration. It is a company that has fully established the industry 4.0 structure and has been implementing it for years.

In our Electrical Panel Manufacturing Workshop, Manufacturing, and field assembly of ADP, MCC, Compensation, PLC, RIO, RTU panels are also carried out. PARAGROUP AIS Group of Companies; We take turnkey projects and successfully do every level from panel manufacturing to system project design, from automation software to SCADA Software, Data Collection and Reporting Software, DCS systems with our experienced team.

PARAGROUP, with its great experience gained in different sectors, its command of all PLC and SCADA software, as well as its knowledge in all points such as process, mechanics, electricity, electronics, communication, data processing, integration, aims to provide quality, trouble-free, systems as it should be, not as desired. purposes.

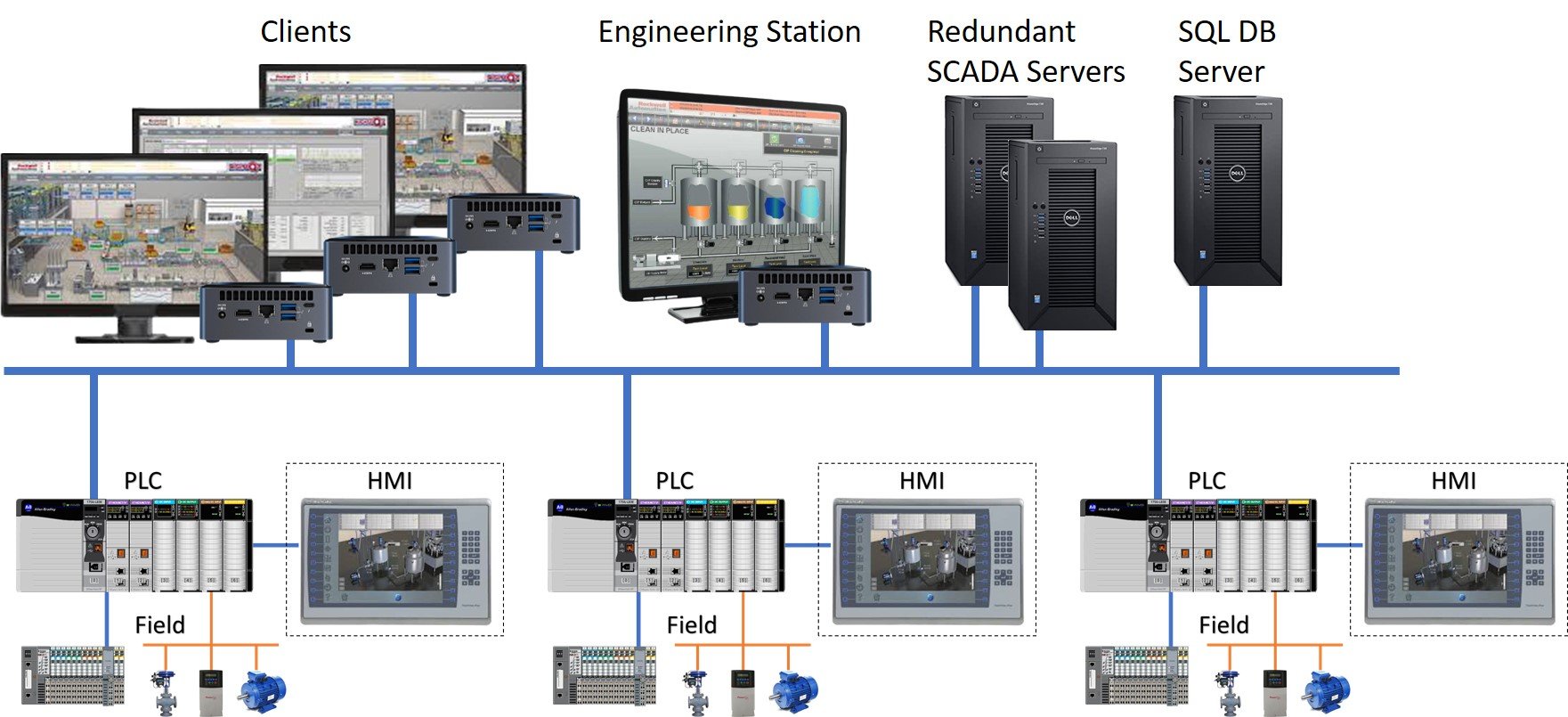

In a factory, it is of great importance for the sustainability of the system that the production lines or processes are completely flexible and that every equipment can be controlled and monitored. With the SCADA (Supervisory Control And Data Acquisition) structure, which is frequently preferred in automation systems, the entire production line, one or more processes and the meaningful counterparts of all kinds of analog and digital signals in this process, diagnostic data of devices and other process-related data are understood thanks to the graphic design. and usable display and control of the system can be done.

Thanks to the SCADA structure, production and processes are monitored and controlled from a single point, and ultimately, it provides a serious profit to the factory with its advantages in time, cost and quality.

We design and install our control systems at the most optimum level with Siemens, Delta and Omron brands that we use in PLC and Scada systems. We work with leading brands in the sector, such as Schneider and Phoenix Contact, in electrical projects.

Our software and engineering solutions include, but are not limited to, control software development, data analysis and visualization, and systems integration. We also offer customized software solutions to meet the needs of our customers.

In addition to providing these industrial automation solutions, we offer ongoing maintenance and support to ensure our customers’ systems are always operating at optimum performance.

We are confident that our expertise and experience in industrial automation will enable us to provide our customers with the best possible solutions for their needs. We would be happy to discuss your specific requirements and provide a quote to meet them.

PARAGROUP, with its great experience gained in different sectors, its command of all PLC and SCADA software, as well as its knowledge in all points such as process, mechanics, electricity, electronics, communication, data processing, integration, aims to provide quality, trouble-free, systems as it should be, not as desired. purposes.

In a factory, it is of great importance for the sustainability of the system that the production lines or processes are completely flexible and that every equipment can be controlled and monitored. With the SCADA (Supervisory Control And Data Acquisition) structure, which is frequently preferred in automation systems, the entire production line, one or more processes and the meaningful counterparts of all kinds of analog and digital signals in this process, diagnostic data of devices and other process-related data are understood thanks to the graphic design. and usable display and control of the system can be done.

Thanks to the SCADA structure, production and processes are monitored and controlled from a single point, and ultimately, it provides a serious profit to the factory with its advantages in time, cost and quality.

We design and install our control systems at the most optimum level with Siemens, Delta and Omron brands that we use in PLC and Scada systems. We work with leading brands in the sector, such as Schneider and Phoenix Contact, in electrical projects.

Our software and engineering solutions include, but are not limited to, control software development, data analysis and visualization, and systems integration. We also offer customized software solutions to meet the needs of our customers.

In addition to providing these industrial automation solutions, we offer ongoing maintenance and support to ensure our customers’ systems are always operating at optimum performance.

We are confident that our expertise and experience in industrial automation will enable us to provide our customers with the best possible solutions for their needs. We would be happy to discuss your specific requirements and provide a quote to meet them.